Tools for tube bending.

We are proud to have our own tool production. We use the best materials and technologies to manufacture the tools used in our tube bending machines. The main tools include bend die, wiper die, clamp die, pressure die and mandrel. By making the tools ourselves, we can ensure the highest quality and optimal performance in our machines. Contact us to get more information about our tool production and tube bending machines.

Quick reference for tubebending

Do you need help with pipe bending? For minor problems, we have created a quick reference for pipe bending. Visit the page to get answers to any problems. If the problems persist, please contact service.

Design and construction of tube bending tools

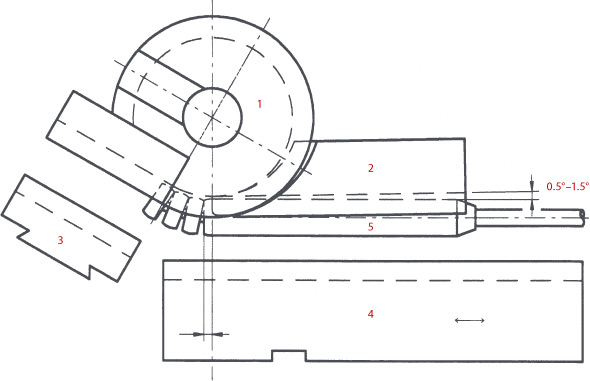

1. Bend die

Made of hardened steel and with the fixed jaw screwed or welded for optimal transition between straight part and radius. For increased quality, the profile can be deepened or made elliptical

2. Wiper die

For tighter radius and thinner wall thicknesses. The table on the right shows at which radii and wall thicknesses support shoes are recommended. The support shoes are manufactured in steel or Ampco.

3. Clamp die

Made of hardened steel. Recommended lock length 3 x pipe diameter. For shorter lock lengths, the profile can be grooved for a better grip. In other cases, recesses are milled for bracket in bracket. In some cases without a straight span.

4. Pressure die

Made of hardened steel. If a fixed (stationary) support rail is used, the support rail length is recommended to be 4 x the diameter of the pipe. In case of running support rail or support rail push-on, the length is recommended to be 2 x the pipe diameter plus half the circumference of the profile board (bending to 180 degrees).

5. Mandrel

For tight radius and thin wall thicknesses. Manufactured from steel or Ampco. The table on the right shows which type of mandrel is recommended for each radius ratio, wall thickness and bending angle.