Herber Engineering AB, a part of Duroc ab

- +46 (0)370 69 96 68

- service@herber.se

Setting of pipe bending tool for tension bending.

Mounted so that the fixed jaw lies parallel to the bending direction.

Check that the height matches the profile board and that the slope is parallel to the slope of the profile board. Adjust the locking pressure so that the pipe does not slide in the slopes during bending.

Insert a tube into the locking jaws and lock this. Slide the support rail against the pipe and lock. In principle, the support rail should lie against the pipe without pressure. If necessary readjust in small steps.

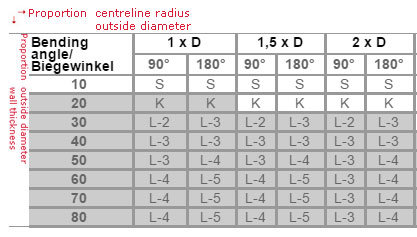

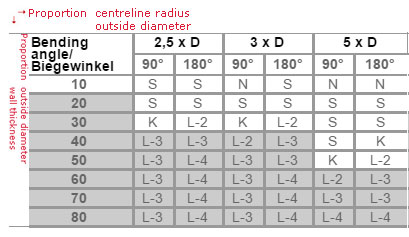

Select the type of mandrel according to the table. Set the mandrel so that part of the mandrel body, max approx. 0.5 x the inner diameter of the pipe, located in front of the center of the tool. Try different modes for best results.

Lock a tube between the locking jaws and place next to the support rail. Then push the support shoe forward as far as possible, the tip should then lie almost in front of the center of the profile board, and lock. The support shoe must lie parallel to the support rail or with the rear part slightly further from the support rail.

Wiper die is recommended when the ratio outside diameter/wall thickness is within the gray field.

N = No mandrel

S = Standard mandrel

K = Cold thorn

L = Link mandrel (The number indicates the recommended number of balls in the link mandrel.

If you need more information about the tools, or other help. We are always available.

See our full guide on how to go about tube bending with a Herber machine.

Herber Engineering AB manufactures advanced tube bending machines (electric and hydraulic) for cold forming of pipes and profiles. For you as a customer, precision, accuracy and flexibility are crucial and that you are secure with the choice of supplier. Therefore, we manufacture all pipe bending machines completely according to the individual customer’s needs and requirements.